Your First Choice for Quality Custom Aircraft Engines

Quality Engine Overhauls

What makes The New Firewall Forward engine a superior choice for your next purchase?

The customer has the option of factory new cylinder replacements or cylinders overhauled by our certified cylinder facility.

Read moreServices

Engine Overhaul

Give your engine the facelift it deserves!

Our qualified staff and proven practices ensure that your engine will perform as well or better than when it was new, We spend time on your engine & it gets the personalized attention that the factory can’t. We give it the “custom” care it deserves.

Core Exchange

Customers love our engine core exchange program.

Click for more information on how to proceed with a core exchange

STC’s

Supplemental Type Certificate

A supplemental type certificate (STC) is an FAA approved major modification or repair to an existing type certified aircraft, engine or propeller.

FAQ’S

-

I underst and I should cut the filter open each time I change the oil. What should I be looking for?

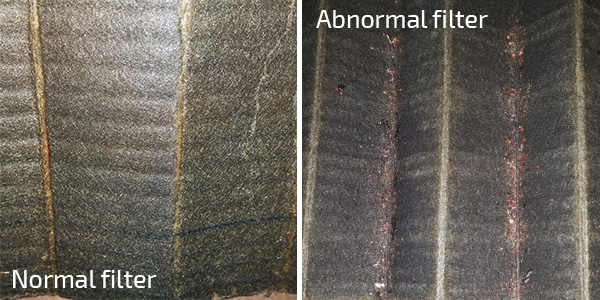

Here is what a normal filter and abnormal filter look like.

Normally, there should be nothing but oil in your filter. Anything other than oil should get your attention. If your filter has large pieces of anything (steel, aluminum, copper alloy, silicon, carbon), you should send it away to have it analyzed. You can send it to an oil analysis company or a good engine shop (like The New Firewall Forward) that can perform a proper analysis.

Large is considered to be anything as large as the head of a straight pin.

Large pieces are scary because they indicate something is coming apart. And, whenever engine pieces come apart, continued operation of the engine is going to change. It’s just a matter of “how soon & what kind of change will occur?”

You should also be concerned about large amounts of small particles. A small particle is considered to be not quite as large as the point of a pin. A large amount is 2 or 3 particles between the several folds of your filter (like the pic below. An occasional r andom flake of metal may not be serious, but you should find out where it is coming from. Some metal is more dangerous, but all metal that is large enough to see, is large enough to do damage as it goes through the engine.

FYI, inspection of the oil filter is essential. Oil analysis helps, but due to the nature of the oil analysis process, larger pieces can slip through the analysis. We frequently see engines that have not been flagged by oil analysis, with major internal metal contamination damage. Please, take the time, or have your mechanic cut the filter open to check for contamination.

-

Does finding metal in the oil mean my engine is toast?

Not necessarily. We commonly perform engine teardowns for metal contamination, prop strike damage, lightning damage, fuel contamination, etc.

We are investigating the extent and nature of the damage. If the engine still has lots of life left (lots of hours before TBO), many times, we can repair/replace damaged components, test the engine’s operation, and return it to certified airworthy status, where it can continue to operate to/or beyond TBO.

We can also take advantage of the engine being apart to replace, repair, or overhaul critical components that will extend the life of the engine.

In the case of prop strikes, fuel contamination, lightning strike, etc., insurance companies will often pay for the inspection/repair. Many times, we can save the customer money by performing an inspectionin conjunction with an overhaul.

-

Why are engines torn down and inspected after what seem like minor prop strikes?

Safety. Both the manufacturers (engine and accessory) and the FAA want to verify that the prop strike hasn’t affected a critical component that can cause it to fail sooner (or later). Engines are more delicate, in some senses, than they appear. Even a slowdown due to running through high water or high vegetation could affect the alignment or stress on gears and bearings (even if the prop wasn’t bent or the crankcase wasn’t cracked as a result).

A case in point would be the gears and fittings in magnetos and prop governors. The manufacturers of these accessories require a thorough inspection to assure that some slight misalignment from a current incident won’t lead to a catastrophic failure in a few hours.

TCM even requires two non-destructive tests (magnaflux and ultrasound) whenever a 360’s, 520’s, and 550’s crankshaft is inspected to ensure internal structural continuity.

-

What is involved in R & R?

When we remove an engine, we photograph the engine and installation, so we can replicate (or improve) the original installation when we’re putting the engine back in.

We also like to refurbish and improve on the baffles and baffle seals whenever possible, because the life of the engine depends on getting proper cooling to all the engine components. Many times, over the years, the aluminum baffle material cracks, bends, or breaks so proper cooling is not possible.

Also, the flexible baffle seals wear, crack, and allow air to escape into the cowling where it is not needed (robbing the areas that need cooling of valuable cooling air).

This is also an opportune time to replace hoses, seals, scat tubing, and engine shock mounts. Basically, most rubber (or rubber-like) components, deteriorate after about 10 years (depending on use and climate).

While the engine is out, we clean the engine compartment, inspect all the fittings, wiring, ductwork, and connections so we get a smooth installation and so the engine can go to/or beyond TBO before major work is required.

Next comes the installation itself. While the engine is out (in the case of an overhaul), the hardware is inspected, cadmium plated (or replaced). So it will resist corrosion while it goes the distance with the engine.

After it is installed and rigged, our technicians run the engine while monitoring it (pressures, temperatures and flows) on the aircraft ( and independent) instruments. Once the mechanics are satisfied, that it is running right, the aircraft is flown at least twice, and de-cowled, inspected and tweaked.

We have to prove the engine to ourselves, to you, and to the FAA before we can re-certify it as airworthy.